Seventy-four percent of customers now shop across more than one channel during every purchase. This creates new demand-planning and experience challenges for even the most celebrated brands.

If inventory isn’t available wherever your customer happens to be, sales are at risk—even if you nail every other aspect of the experience. How can you make sure stock is available everywhere at once?

With a competitive focus on customer acquisition costs (CACs) and delivery times, many retailers are trying to address this challenge by expanding their warehouse locations to both coasts in North America or, in some cases, to micro-warehouses dotting areas where customers are concentrated.

But is this the right approach? Additional warehouses can speed delivery, but they don’t help lower CAC. Even if they did, can your brand afford to limit your inventory visibility when product lifecycles are short?

There’s a better way. By allocating inventory strategically across your channels to reach 100 percent inventory availability, you’ll have more inventory available in each channel, higher conversion rates, and more conversion opportunities.

The Old Inventory Model

The old model for Ecommerce inventory management held the bulk of inventory at one or more distribution centers to ensure that inventory was available online and set aside to fulfill online orders. But this strategy can result in significant inventory imbalances between channels, creating an uneven customer experience caused by the following scenarios.

1. Warehouse has low stock, but stores are well-stocked.

When the warehouse has low stock but stores have ample stock, the online channel is depleted and inventory ages longer on the store shelves. In this scenario, you face lost sales, delays, and higher shipping costs from transferring inventory back to the warehouse—or, worse, marked-down or written-off inventory in stores.

This can be especially painful when a new style has high demand, resulting in lost conversions or lower margins. If you are carrying products that can be found elsewhere, forget it.

2. Stores have low stock, but the warehouse is well-stocked.

Many shoppers prefer the hands-on experience of in-store shopping. They might also just enjoy the social aspect. When a desired size is out of stock in-store, you’ve got to be ready with great customer service. There are only a few options in that moment: Staff can direct the customer to another style, convince them to order from the online channel, or accept that the sale might be lost.

Either way, it’s not the ideal experience and, if handled poorly, is the kind of thing that customers tell their friends about.

The Channel Balance Method

“Channel balance” is a new approach to inventory that results in increased inventory availability and happier customers across all retail channels. This approach simply acknowledges and addresses the reality of today's customer journey. It doesn’t require you to purchase and hold more inventory; instead, you optimize inventory value by making that inventory 100-percent available.

In the old inventory model examples above, significant amounts of inventory are not available to the customers who want to buy. With so many shoppers now bouncing across channels during their journey, you need close to 100 percent of your inventory to be visible and available for sale.

You can make that happen with the following techniques.

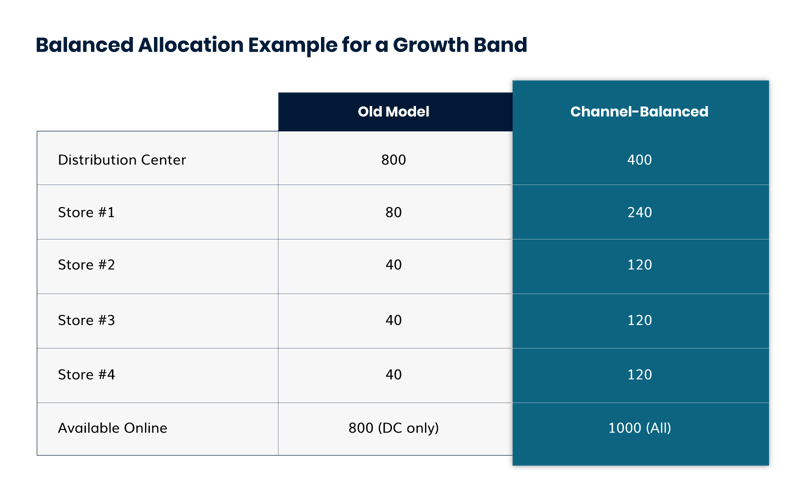

Balanced Allocation

The first step in improving your channel balance is to review your allocation strategy. Because you will be making all units available for sale online rather than just the quantities in the distribution center, you can allocate more inventory to your stores.

The practical impact is that you will have more inventory available for sale both online and in-store, ensuring that in-store customers are able to find the style and size they want during their visit.

As you can see from the example, this simple approach increases available inventory online by 25 percent and in-store by 200 percent—all by adjusting your approach. Many brands that have implemented this strategy have seen their sell-through double almost immediately.

Allocate based on your retail footprint, customer density, and store traffic. There is no general rule about what ratio of stock to allocate where. Those decisions should be based on your experience and trends in the category and season. Review and adjust as you go.

Safety Stock

Accumula protects against sell-outs and oversales of in-store inventory by applying a buffer quantity to each location inventory called Safety Stock. The Safety Stock value is subtracted from the available inventory quantity at the location, category, style, or SKU level, ensuring stock will not be fully depleted by the online channel.

This guarantees not only that in-store customers will have stock to choose from but also that store staff won’t adjust out or hide stock for sale later (seriously, that happens).

Many brands also apply a buffer to their distribution centers, protecting against oversales from inaccurate inventory, which in turn reduces customer service issues.

Make In-Store Inventory Available for Sale Online

Once your allocation is performed and holdbacks are set, make your in-store inventory available for sale online. Choose which stores will be included in your available for sale inventory and ensure that each store team has the process training to fulfill and ship orders.

The best practice is to bring a few stores on at a time to ramp up and address any organizational challenges that arise from new processes.

The Halo Effect

Once these inventory management processes are in place, a number of customer-centric fulfillment options become possible, giving your customers more choice and convenience. In fact, the added visibility across channels also tends to have a positive impact on your internal teams:

“Accumula didn’t just integrate our operations and grow our sales, it had a cultural impact on our teams that was game-changing. We now understand our Customers much better.”—Peter Fuller, Ecom Manager, Bella Ella

These fulfillment options should include the following:

In-Store Pickup (BOPIS)

With wider inventory available in stores, in-store pickup becomes a more feasible and reliable option for customer orders. This helps drive store traffic and sales, with 85 percent of BOPIS shoppers buying additional items when they make their pickup.

In-Store Availability

You can also leverage the online channel to directly drive in-store sales. With store inventory integrated into your stack, displaying in-store availability on your website becomes a simple win to let shoppers know exactly what stock is available where.

Ship from Store (SFS)

With 100-percent inventory availability, an order management system (OMS), and integrated software like Shipstation, your teams will be able to fulfill orders from the store. If a warehouse isn’t the best fulfillment option, Accumula can even prioritize fulfillments to stores by fewest and fastest shipments to cut delivery times and costs.

Allocating inventory strategically across your channels using a channel balance strategy can help align your entire organization to the customer. In-store teams now have the inventory they need readily available and can help fulfill online orders, cutting shipping times to local customers. Meanwhile, online teams have even more inventory and traffic drivers available to satisfy shoppers.

A 100-percent inventory strategy can expand your customer reach and make your inventory dramatically more efficient. Expanding fulfillment options to retail stores is a valuable by-product of this shift, contributing to a better customer experience.